What makes LVL products so great

Posted: July 30th, 2020

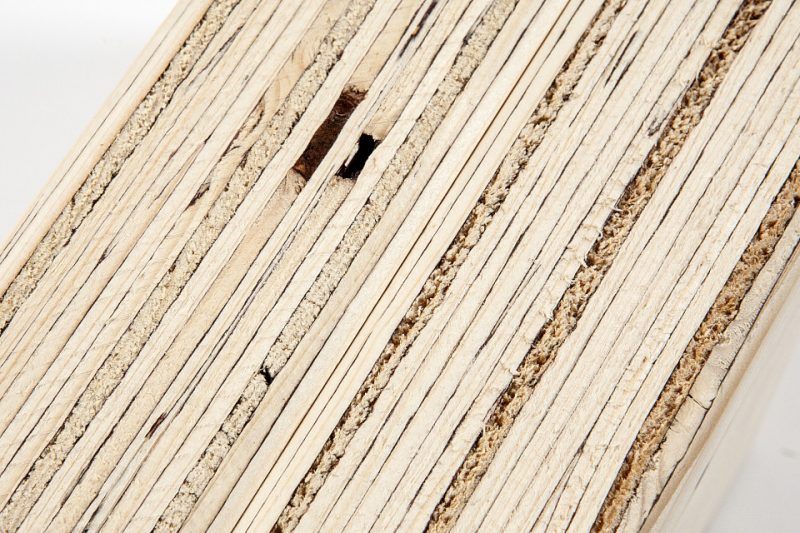

There is a new kid on the block and it is stronger, more durable and more versatile too. LVL (Laminated Veneer Lumber) is a wood-based product and it’s most common use is as structural timber. It is manufactured by peeling sheets of timber from a log. Then cutting them to any given size, pressing a number of sheets together to form a length of engineered timber. This process makes LVLs quite unique and gives them a number of advantages over standard timber products.

Strength & Durability

The strength properties of LVLs come from the manufacturing process. During the process, the veneers (the individual sheets of timber that make up the LVL) will dry and the veneers are placed with the grains running in the same direction. The veneering process also randomizes any defects in the timber or eliminates them altogether. For example, you can remove a wood knot when you cut the veneers to size. Or, if that is not possible, a single wood knot is spread out over different areas of the veneer taking away any of its negative effects.

As a result LVL products are incredibly uniform. The extra strength makes them comparable to solid timber, concrete and steel. LVLs, being engineered wood products, means they are much less prone to warping and shrinking. Which in turn, means you get consistently straighter timber. Another aspect that sets LVLs apart is that they can be up to 30% lighter than the equivalent size hardwood.

Manufactured to your need

Being a manufactured timber product means that LVLs are hugely versatile. They can be used in place of almost any regular timber in most situations. This is made possible due to the ability for LVLs to be made in whatever size you need and a huge range of shapes. The added strength of LVLs means a single length can span long distances and support heavier loads.

Sustainable and cost-effective

Timber has been described as the ‘Ultimate Renewable’ by the Australian Government and for good reason. As long as our timber industry is well managed this wonderful resource will remain plentiful and the top choice for sustainable building materials. Compared to other materials such as concrete and steel, the amount of energy that goes into producing timber products from start to finish is much less. The manufacturing process ensures the timber resources are used to their full potential and the least amount is wasted. LVLs are also highly cost-effective, they are able to deliver better performance, versatility and variety for less than other options. Being able to source LVLs at whatever size you need means less time cutting and joining smaller lengths of regular timber which also means less time spent on a job.